How to implement a barcode system, step by step

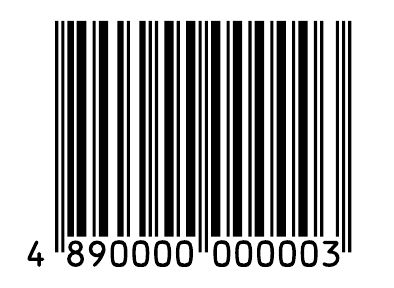

A barcode makes it easy to manage your product information and speed up business transactions. Therefore, it is one of the most important tools in your business. Regardless of the code you want to include in your company, be it the UPC, EAN or similar, the steps you have to take will be similar in either case.

Implementation of the barcode in the company

The first thing to do when implementing a barcode is to obtain your company prefix. This code should be part of the barcode behind the country code, so that your company can be identified as the owner of that particular product. This company prefix will be 4-5 digits long and unique.

On the other hand, you have to create a database with all your products identified with a numerical code. Finally, the code must be completed with the check digit, which is calculated by an algorithm using the twelve already established, and placed at the end of the code.

The barcode has to meet specific specifications. It must meet a series of requirements regarding dimensions, location and color so that it can be read without difficulty.

Another need to be able to implement the bar code in the company is to have computer software that generates symbols, as well as a bar code printing system. The complexity of this need makes many companies resort to hiring these services. In addition, to facilitate the use of a barcode system, it would be best to have a wireless system to be able to automatically consult the online database.

RF system

The radiofrequency system is the basis of a good implementation of the bar code, since it is necessary for the rapid reading of the code symbols, without the need to enter the 13 digits of the code by hand.

The best way to include the laser readers is through a wireless radio frequency network that automatically sends the information. This is processed in real time and can be monitored remotely; and for the effective use of this method, it will be necessary to have a solid wireless access point, also called WAP.

4 more steps to implement the barcode

Throughout the implementation process you will also need to take other steps to ensure that you achieve a quality and efficient barcode system. They are a series of steps aimed at perfecting your system which, if you have followed the instructions this far, is already effective.

Identify reading points: Before making aesthetic decisions about size or color, it is necessary to analyze the potential reading points where your code will need to be read.

Depending on whether your product will be read at the point of sale, in the warehouse, in special settings (such as hospitals, for example), or in any combination of those three points, certain decisions will need to be made for the next point.

Decide: type, dimensions and color of symbols. The aesthetics of the barcode must be a conscious decision, since it will be part of the packaging whether you like it or not. The type of symbol is the most crucial when it comes to knowing where to read it; however, both dimensions and color will be creative decisions only limited by barcode standards, which are limited to ensuring that they can be read.

Select the location of the code: the location of the code on the product is a practical matter that must be in a comfortable place for reading and away from the most vulnerable places to avoid damage.

Develop a quality plan: it seems like a truism, but a quality plan is the icing on the cake for your barcode to be effective and, above all, to last over time. The codes need to be able to be readable over several years, especially if the product is not perishable, since they can be read at any time.